Factory source Turning Milling - Sheet Metal – Lead

Factory source Turning Milling - Sheet Metal – Lead Detail:

Sheet Metal Fabrication

Our custom sheet metal services offer a cost-effective and on-demand solution for your manufacturing needs. We have high speed, state of the art metal fabrication equipment that is best suited for producing durable, end-use metal parts with repetitive, low-to-high volume and high-mix production runs that are fabricated to your specifications.

Sheet metal work is the process of metalworking that forms new products from various types of sheet metal. Heating processes are used to harden or soften sheet metal by heating or cooling it until it reaches the desired level of hardness, and also so it is in a form that is workable. Several important techniques may be used in the heat treating process, including annealing, quenching, precipitation strengthening and tempering

How Sheet Metal Fabrication Works

There are 3 common stages in the sheet metal fabrication process, all of which can be completed with various types of fabrication tools.

● Material Removal: During this stage, the raw workpiece is cut to the desired shape. There are many types of tools and machining processes that can remove metal from the workpiece.

● Material Deformation (forming): The raw metal piece is bent or formed into a 3D shape without removing any material. There are many types of processes that can shape the workpiece.

● Assembling: The completed product may be assembled from several processed workpieces.

● Many facilities offer finishing services as well. Finishing processes are usually necessary before a sheet metal-derived product is ready for the market.

Applications for Sheet Metal

Enclosures – Sheet metal offers a cost-effective way to fabricate product device panels, boxes and cases for a variety of applications. We build enclosures of all styles, including rackmounts, “U” and “L” shapes, as well as consoles and consolets.

Chassis – The chassis we fabricate are typically used to house electromechanical controls, from small handheld devices to large industrial testing equipment. All chassis are built to critical dimensions to ensure hole pattern alignment between different parts.

Brackets –builds custom brackets and miscellaneous sheet metal components, well-suited for either lightweight applications or when a high degree of corrosion-resistance is needed. All hardware and fasteners that are needed can be fully built in.

Capabilities

|

Processes |

Laser cutting, Plasma cutting, Waterjet cutting, CNC punching, CNC bending, welding, assembling, etc |

|

Materials |

Aluminum, Steel, Stainless steel, brass, copper |

|

Finishes |

Anodized, sandblasted, polished, powder coated, electroplated, etc |

|

Inspection |

1st Piece Inspection, In-Process, Final |

|

Industry focus |

Agriculture, Truck, automotive, electronics, medical, furniture, hardware, machinery, etc |

|

Additional services |

CNC Machining, CNC Turning, Metal Stamping, Sheet Metal, Finishes, etc |

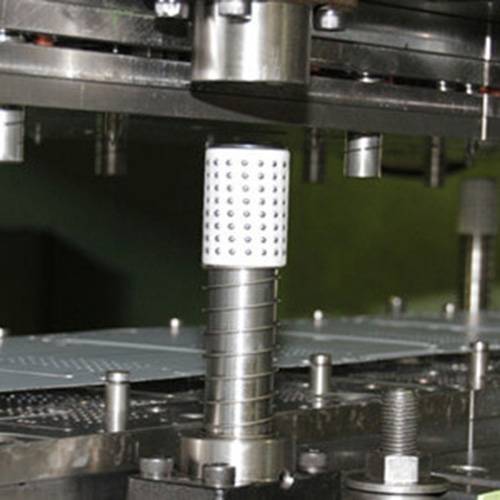

Product detail pictures:

Related Product Guide:

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Factory source Turning Milling - Sheet Metal – Lead , The product will supply to all over the world, such as: Belize, Chile, Nigeria, We've been always creating new technology to streamline the production, and give products with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We are going to present our best service to satisfy all your needs! Remember to contact us right away!

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.