CNC turning is a manufacturing process that uses computer-controlled machines to cut and shape metal and other materials. It is a highly efficient method of producing precision components for various industries, including aerospace, automotive, energy, and more.

Typical CNC Turning Operations

1. Turning

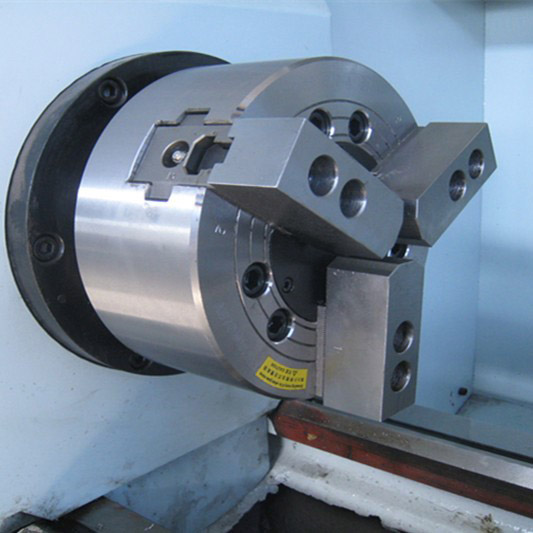

Turning is the most common operation performed on CNC lathes. It involves rotating the workpiece while a tool cuts or shapes a specific area. This operation is used to create round, hex, or square stock, among other shapes.

2. Drilling

Drilling is a hole-making operation that uses a tool called a drill bit. The bit is fed into the workpiece while it rotates, resulting in a hole of a specific diameter and depth. This operation is commonly performed on hardened or thick materials.

3. Boring

Boring is a precision machining process used to enlarge the diameter of a pre-drilled hole. It ensures the hole is concentric and has a smooth surface finish. Boring is typically performed on critical components that require high tolerances and surface finish quality.

4. Milling

Milling is a process that uses a rotating cutter to remove material from the workpiece. It can be performed in various ways, including face milling, slot milling, and end milling. Milling operations are commonly used for shaping complex contours and features.

5. Grooving

Grooving is a process that cuts a groove or slot into the surface of the workpiece. It is typically performed to create features such as splines, serrations, or slots required for assembly or performance. Grooving operations require specialized tooling and precision feeding to maintain the required dimensions and surface finish.

6. Tapping

Tapping is a process that cuts internal threads in the workpiece. It is typically performed on holes or existing threaded features to create female threads for fasteners or other components. Tapping operations require precise feed rates and torque control to ensure thread quality and fit-up tolerance.

Summary of Typical CNC Turning Operations

CNC turning operations cover a wide range of processes that involve rotating or positioning the workpiece relative to the tooling. Each operation has specific requirements, tooling, and feed rates that must be considered during the manufacturing process to achieve the desired results with precision and repeatability. The selection of the appropriate operation depends on the geometry of the component, material type, and tolerance requirements for the application.

Post time: Oct-08-2023