From 2010, we have started to provide fiberglass, titanium CNC machining parts for our client, who is one of largest America Military Companies. Today we’d like to say something about titanium material for your reference.

Titanium alloy has high strength, low density, good mechanical properties, toughness and corrosion resistance advantages. But its process performance is poor, it’s difficult to cutting and machining, during the hot work, it is very easy to absorb impurities such as nitrogen and nitrogen. Besides, titanium has poor wear resistance, so the production process is complex.

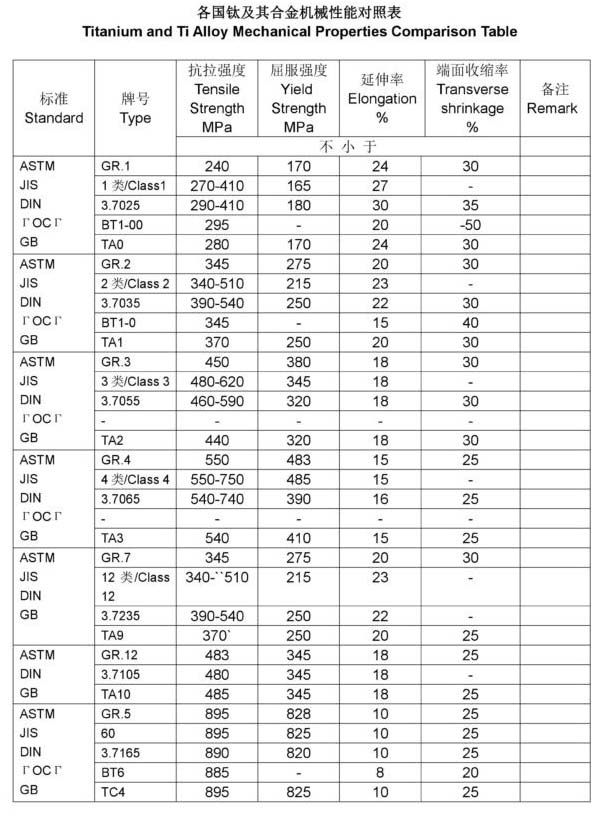

Due to the development of the aviation industry, the titanium industry has grown at an average annual rate of about 8%. The most widely used titanium alloys are Ti-6Al-4V (TC4), Ti-5Al-2.5Sn (TA7) and industrial pure titanium (TA1, TA2 and TA3).

Titanium alloy is mainly used for the production of aircraft engine compressor parts, followed by rockets, missiles and high-speed aircraft structural parts. Titanium and its alloys have become a corrosion resistant structural material. Also used in the production of hydrogen storage materials and shape memory alloys.

Because titanium material cost is not cheap, and it’s too strong to cutting and machining, that’s why titanium parts cost is high.

Post time: Jan-07-2021