Wholesale Price China Sheet Metal Service - Finishes – Lead

Wholesale Price China Sheet Metal Service - Finishes – Lead Detail:

Finishes

Surface treatment is the surface of the substrate material to form a layer with the matrix of the mechanical, physical and chemical properties of the surface layer of the process. The purpose of surface treatment is to meet the product corrosion resistance, wear resistance, decoration or other special functional requirements. For metal machining parts, more commonly used surface treatment methods are mechanical grinding, chemical treatment, surface heat treatment, spray surface, surface treatment is the surface of the workpiece cleaning, cleaning, deburring, to oil, descaling and so on.

What Is Industrial Metal Finishing?

Metal finishing is an all-encompassing term used to describe the process of placing some type of metal coating on the surface of a metallic part, typically referred to as a substrate. It can also involve the implementation of a process for cleaning, polishing or otherwise improving a surface. Metal finishing often consists of electroplating, which is the process of depositing metal ions onto a substrate via an electric current. In fact, metal finishing and plating are sometimes used interchangeably. However, the metal finishing industry includes a wide range of processes, each offering its own user benefits.

Industrial metal finishing can serve many valuable purposes including:

● Limiting the impact of corrosion

● Serving as a primer coat to promote paint adhesion

● Strengthening the substrate and increasing wear resistance

● Reducing the effects of friction

● Improving the appearance of a part

● Increasing solderability

● Making a surface electrically conductive

● Enhancing chemical resistance

● Cleaning, polishing and removing surface defects

Surface treatment methods

Mechanical processes

Polishing

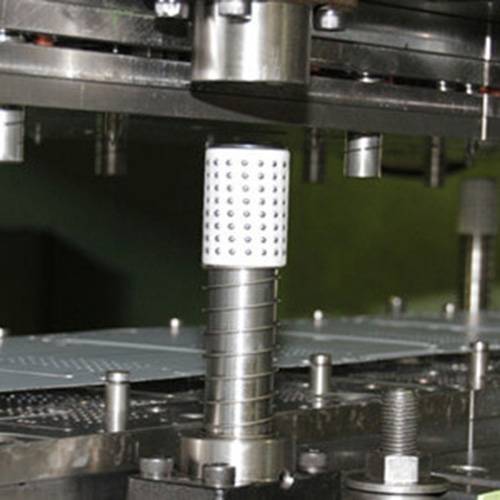

High-quality spindle drives with individually adjustable speed for optimum polishing of the workpiece.

Lapping

Ultrasonic-assisted lapping and polishing process for small parts.

Internal polishing

With special processes, the internal surface of straight, normal and reduced tubes can be improved.

With these processes, an excellent surface quality can be achieved depending on the starting material.

Vibratory finishing

The workpiece is placed in a container with grinding wheels. Oscillating motions cause the edges and rough surfaces to be removed, thus improving the surface quality.

Sand and glass pearl blasting

For deburring, roughening, structuring or matting surfaces. Depending on the requirements, various blasting media and setting parameters are possible.

Chemical processes

Electropolishing

Process

Electropolishing is an electrochemical removal process with an external power source. In an electrolyte specially adapted to the material, the material is anodically removed from the workpiece to be machined.

This means that the metallic workpiece forms the anode in an electromechanical cell. The metal prefers to dissolve on uneven surfaces due to tension peaks. The removal of the workpiece is carried out without stress.

Applications

Reduction of surface roughness, improvement of surface corrosion resistance, fine edge rounding.

Electropolishing can only be applied to the outer surfaces of the cannulas.

The part size is limited to max. 500 x 500 mm.

Below are mainly finishes we usually take:

Sand Blast

Anodized

Electoplate

Polished

Powder Coated

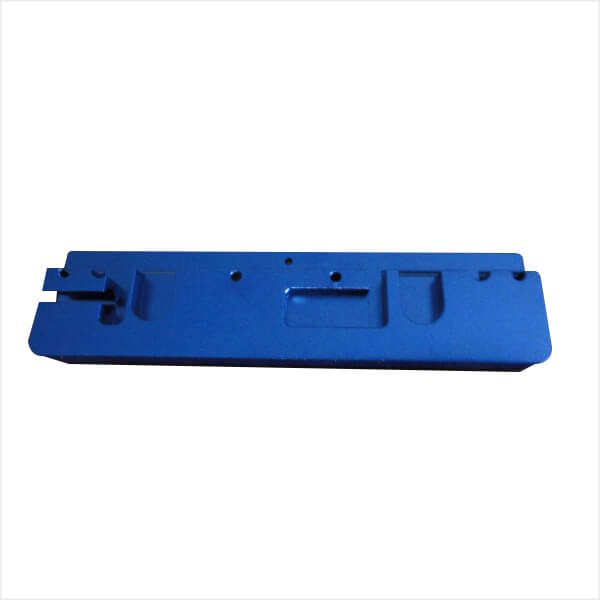

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with Wholesale Price China Sheet Metal Service - Finishes – Lead , The product will supply to all over the world, such as: panama, British, Ecuador, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.