News

-

What are the parts processed by CNC turning?

CNC turning is a manufacturing process that uses computer-controlled machines to cut and shape metal and other materials. It is a highly efficient method of producing precision components for various industries, including aerospace, automotive, energy, and more. T...Read more -

Metal Stamping: A Key Component in the Development of Eco-Friendly Vehicles

Metal Stamping: A Key Component in the Development of Eco-Friendly Vehicles The automotive industry is constantly looking for ways to reduce its impact on the environment while maintaining performance and efficiency. One of the key areas where significant progress can b...Read more -

What is the difference between steel, aluminum and brass sheet metal?

Sheet metal is widely used in the manufacturing industry and there are three main sheet metal material types: steel, aluminum and brass. Although they all provide a solid base material for product production, there are some notable nuances in terms of physical properties...Read more -

What grades of brass do you know?

1, H62 ordinary brass: has good mechanical properties, good plasticity in hot state, plastic can also be cold state, good machinability, easy brazing and welding, corrosion resistance, but easy to produce corrosion rupture. In addition, the price is cheap and is a common...Read more -

Factory supplied China Laser Cutting Stainless Steel Sheet Metal

Nearly 160 million workers were commemorated across the US on Monday as the annual Labor Day celebration unofficially marks the end of summer and gives families in some communities one last chance to reunite with friends and family the day before the start of the schoo...Read more -

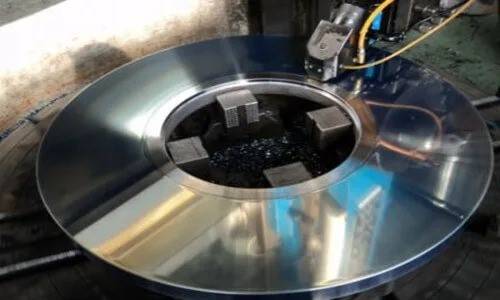

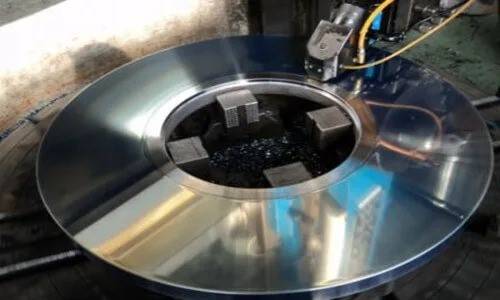

How to turning plane threads in machining process?

The plane thread is also called the end thread, and its tooth shape is the same as the rectangular thread, but the flat thread is usually the thread processed on the end face of the cylinder or the disc. The trajectory of the turning tool relative to the workpiece when machining a plane thread is...Read more -

The Working Principle Of Mold Polishing And Its Process.

In the mold manufacturing process, the forming portion of the mold often needs to be surface polished. Mastering the polishing technology can improve the quality and service life of the mold and thus improve the quality of the product. This article will introduce the working principle and process...Read more -

Explanation And Analysis Of Crankshaft Manufacturing Technology

Crankshafts are widely used in engines. Currently, the materials for automotive engines are mainly ductile iron and steel. Due to the good cutting performance of ductile iron, various heat treatments and surface strengthening treatments are performed to improve the fatigue strength, hardness and ...Read more -

How to machine thread in machining center?

Machining thread in machining center is one of the most important applications. In the process of thread processing, the quality and efficiency of the machining directly affect the quality and efficiency of the part. Below we will introduce the thread processing methods commonly used in actual ma...Read more -

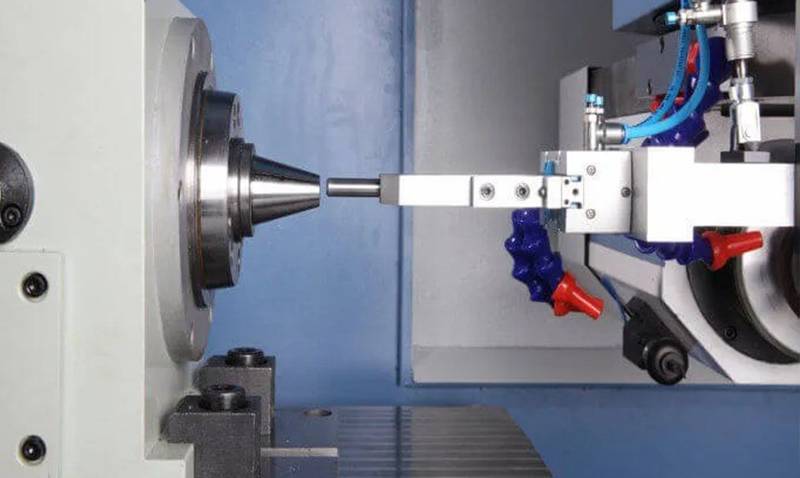

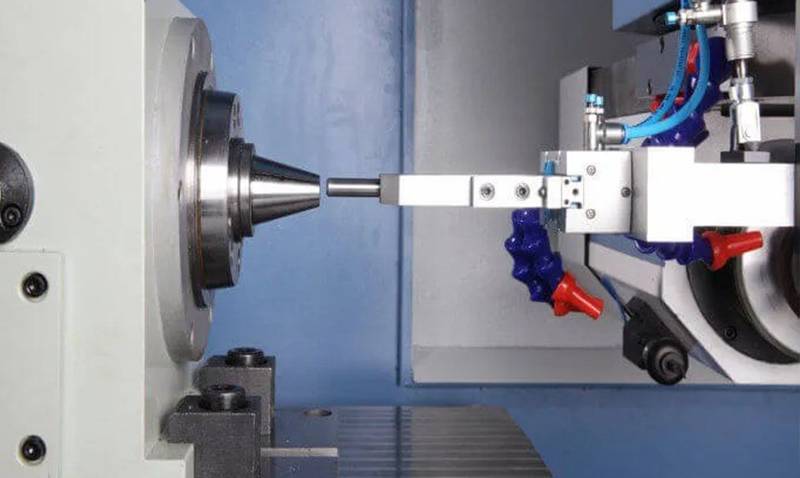

CNC lathe processing grinding the fundamental characteristics

CNC lathe processing grinding the fundamental characteristics are: 1.Grinding power is high. Grinding wheel relative to the workpiece for high-speed rotation, usually wheel speed reach35m / s, about 20 times the normal tool, the machine can get a higher metal removal rate. With the development of...Read more -

Anti-corrosion surface treatment of fasteners, it is worth collecting!

Fasteners are the most common components in mechanical equipment, and their function is also very important. However, corrosion of fasteners during using is the most common phenomenon. In order to prevent corrosion of fasteners during using, many manufacturers will take surface treatment after th...Read more -

How To Cut High-strength Steel In Mechanical Production?

High-strength steel is added with different amounts of alloying elements in steel. After heat treatment, the alloying elements strengthen the solid solution, and the metallographic structure is mostly martensite. It has large strength and high hardness, and its impact toughness is also higher tha...Read more